Sustainability is no longer a trend. Neither is it a whim of the next generation, nor an option that can be deliberated. Instead, it’s a cause of the present, one that is being embraced by businesses and consumers alike. With environmental awareness at an all-time high, governments from around the world have committed to creating a cleaner environment for all, placing sustainability at the very top of the global agenda.

Among the many changes stemming from this focus on environmentalism is the revolution of the packaging industry. In 2010, Dutch packaging firm Airopack aimed to replace polluting aerosols with a propellant-free container that was more fitting with modern times. This groundbreaking plastic aerosol, which is powered by air, presents a more sustainable alternative to its predecessors at a time when consumers are increasingly opting for solutions that take better care of the planet.

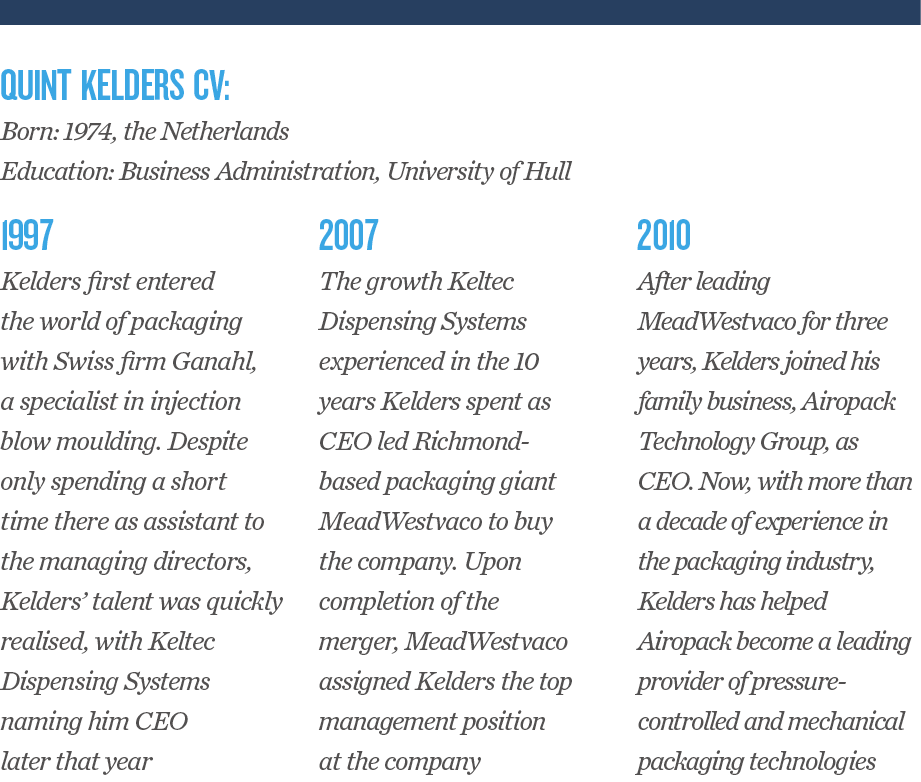

“The future is not so far away anymore,” Airopack CEO Quint Kelders told European CEO. In fact, despite the continued use of traditional aerosols, Kelders firmly believes his company’s progressive products will soon become the norm.

Inspiring innovators

Since the company’s formation, Airopack has consistently looked to stretch the market’s parameters, establishing a family of products with unprecedented features. Kelders puts this down to the company’s desire to “enrich customers’ lives by bringing existing systems to the next level, enabling them to live a more sustainable life”. With this ethos guiding the company, Airopack has consistently pushed the boundaries of what was thought possible in the packaging industry. “We achieved the development of a planet-friendly and innovative aerosol by believing there is always a better way,” Kelders said.

Kelders attributes much of his success to the innovators who went before him. Among his greatest inspirations is his father, Jan Kelders, whom he describes as “a true innovator and inventor”. Often frustrated with malfunctioning or imperfect things, Jan Kelders took it upon himself to find or create new solutions, with the Pritt Stick and the ink ribbon found in typewriters just two of his many inventions. Kelders believes Airopack products are very much created in the same vein as his father’s.

Airopacks are made entirely of plastic, making them lighter, safer and recyclable

But Kelders has also found inspiration elsewhere, with pioneers like Elon Musk and Richard Branson encouraging him to consistently think outside the box. Kelders considers both leaders to have a common drive: “They have a strong determination to transform industries while improving the world at the same time.”

And Kelders’ connection with Branson and Musk becomes even clearer when he describes the ambitions he has for his own company: “My goal with Airopack is to transform the entire aerosol value chain, adapting the systems in such a way that the aluminium propellant aerosol is no longer needed, and the sustainable aerosol is the norm.

“We can already see the positive impact Airopack is having, reducing waste and CO2 emissions while eliciting a favourable response from the industry and other stakeholders.”

Combined forces

Airopack’s growth has coincided with a more general transition towards environmentally friendly practices. People, businesses and governments are all collaborating to enforce a fundamental change in the way we treat the planet. This concerted effort was highlighted in 2016 when 196 countries came together to sign the Paris Agreement – a treaty that aims to curb the rising global temperature.

Kelders believes this agreement has helped set the standard, pushing companies and governments to play a key role in the preservation of the planet. But, despite acting as a sign of progress, Kelders has warned against complacency: “The Paris Agreement plays a key role in this transformation [towards environmentally friendly practices], mainly because of the commitments that were made and the standard that it set.

“But it’s not the Holy Grail; we can’t just feel content it exists and continue on our path. The entire value chain will need to work together to adapt its dynamics and make its processes truly sustainable. As everything is connected, we will only be able to have a truly positive impact if all industries work together.”

There has also been a significant shift in the behaviour of those outside the business domain; ordinary people are now making purchasing choices with a different mindset. “Consumers are increasingly engaged with sustainable policies – to the extent it is a determining factor in their purchasing decisions,” Kelders said. “They are clearly more aware of what is happening in the world, how industries work and the impact they are having on the environment. Put simply, consumers have become more critical and more demanding.

“Several studies show that a third of consumers are now choosing to buy brands they believe are doing social or environmental good. This has led to a significant growth in the number of consumers preferring – and even demanding – sustainable packaging.”

The substitute

As the industry – and, indeed, wider society – calls for the development of sustainable alternatives to everyday products, Kelders believes it is only a matter of time before the traditional, aluminium-propelled aerosol is replaced indefinitely. But this process will not happen overnight – in fact, it has been ongoing for some years now. First introduced to the market in 2011, Airopacks are made entirely of plastic, making them lighter, safer (with no risk of explosion or fire) and recyclable. Unlike their predecessors, Airopacks also replace harmful propellants with air.

Further, these innovative containers can be applied to a wide range of formulation viscosities, from water and toothpaste to sealants. This has led to the rapid adoption of Airopacks in the beauty and personal care sector. But the package’s diversity means there is great potential in other markets as well, notably the pharmaceutical and food industries.

Another advantage of the Airopack is its transparency. While being able to see the contents of your aerosol may seem like a minor detail, the importance of transparency » becomes clear when you take into account the fact that only 40 percent of traditional aerosols are made up of the product itself. In those cans and bottles, the head of the aerosol dominates a large percentage of the space (40 percent), while liquefied propellants take up the rest (20 percent). In contrast, Airopack’s patented containers don’t hide anything: they simply contain and dispense formulas, which don’t include any gas propellants or chemicals.

Beyond the obvious benefits of avoiding air pollution, consumers can also enjoy Airopack’s usability advantages. “Plastic aerosols simply perform better,” Kelders said. “Unlike traditional aerosol cans, Airopacks can be used at any angle – not just vertically – meaning they can dispense until the very last drop. Consumers also prefer our air-propelled dispensers because they provide an uninterrupted and smooth flow, which is not the case with pump sprays.

“The benefits of using Airopacks are also related to the quality of the formulations, as the air-driven system allows manufacturers to offer purer and more effective formulas. What’s more, plastic aerosols are airtight, which means that products are better preserved.”

People, businesses and governments are all collaborating to

enforce a fundamental change in the way we treat the planet

In terms of cost, Airopacks have a beneficial impact on the production chain, both at the time of installation and in the subsequent manufacturing process. This, in turn, ensures customers don’t face a premium when seeking to purchase sustainable products. Airopacks are the same price as traditional aerosols, something Kelders attributes to the company’s new manufacturing site in Waalwijk, the Netherlands.

“The investment in filling machinery for Airopacks is only one third of the investment required for traditional aerosols,” Kelders revealed. “This is possible due to the fact Airopack’s system avoids the use of dangerous propellants, which eliminates costs such as charges in machinery explosion regulations.” Consequently, the use of air-powered aerosols requires less floor space, reducing costs even further.

Exploring new markets

The ongoing green revolution is opening doors for exploration across different industries like never before. Manufacturers are keen to innovate and people are welcoming novel initiatives. In this context, Airopack has broken into several markets, with consumers quickly adopting its sustainable containers. Specifically, the company has high penetration in personal grooming, hair care and air freshening.

“Europe and North America are our main focus because that’s where the ‘A-brands’ with high volumes of aerosols and dispensers are headquartered,” Kelders said. Specifically, the US is absorbing most of Airopack’s production at present.

Looking ahead, the packaging firm’s business could be expanded globally. “As our product can replace traditional aerosols, we could, in theory, target any market with aerosols,” Kelders said. However, Airopack has a clear strategy to conquer industries gradually, prioritising the biggest deals: “We can’t replace all aerosols at once, that’s why we are focusing on the markets with the greatest volumes and margins, such as hair and sun care, food, cleaning and the DIY sector, which includes products like glue.”

In the food market, for example, Airopacks could help cooks and diners add the right quantity of a desired condiment to their dishes. As consumers have entered an age of health consciousness, chemical-free containers are also convenient for those looking for a healthy meal.

But this is just one example of the role Airopack can play for businesses. To make sure its products are adopted universally, the company follows three specific approaches: the first and easiest method is to simply implement air-powered containers with products that perfectly suit Airopacks. The second approach is to help companies make small adjustments in their formulations to fit the containers. Finally, Airopack explores the viability of its clients developing new products that can make use of the packaging technology.

Airopack also offers companies the chance to adapt its range of packaging to their specific identities, with the transparent packaging perfect for branding. Yet, despite all of this, Kelders revealed there is still more to come: “At present, we are developing new versions of our containers, including a ‘freestyle’ version, which will make the outer design even more adaptable to brands.”

A new era

With its disruptive family of clean aerosols, Airopack has raised the bar in the packaging industry, positioning itself at the forefront of a new era of sustainability. In Kelders’ words, the future looks as bright as it is challenging: “Consumer convenience combined with sustainability is our way of building the future. We have to accept the world changes. Energy consumption on the planet is not sustainable in the long term at its current pace. We need to work to bring about solutions for future generations.”

In this area, Airopack has already taken significant action, delivering sustainable products that perform better than their predecessors at no extra cost to the companies that adopt them, or to the consumers who subsequently buy them. Kelders believes it’s this affordability that will be vital to the worldwide adoption of more sustainable processes: “We deliver sustainable behaviour to the consumer at no extra effort or cost. This combination is the business model towards which the packaging technology industry is clearly evolving, and one which all industries must adopt in the future.”

With this in mind, Airopack already has a strategic plan in place to extend its influence around the world. “Due to growing customer demand, we are currently increasing our production capacity from the initial 80 million to 100 million Airopack dispensers per year,” Kelders said. The following step, which is planned for next year, is even more ambitious, with the company investing heavily to double its production volume to 200 million dispensers per year.

“Scaling up our capacity will give us what we need to accomplish our mission of conquering at least 20 percent of the global aerosol market, and replace the polluting cans with our planet-friendly innovation,” Kelders said. As a part of this growth effort, Airopack will unveil new AAA brand creations for clients in a number of different markets.

While Airopack is making significant progress, the packaging industry still has some way to go in the transition towards sustainability. It’s true that awareness is growing, but consumers still accept companies’ use of harmful packaging in the name of convenience.

Kelders believes it is time to break these bad habits and ensure customers are never presented with a choice between sustainability and cost or quality again: “We will keep looking to improve and innovate in order to provide customers with sustainable packaging that is both convenient and cost-effective.”

With a clear set of sustainable principles guiding the way, Kelders is aiming to replace the traditional aerosol once and for all. It’s clear Kelders has inherited his father’s desire for functionality, and his natural proclivity for improvement. It’s fitting, therefore, that the motto that drove Jan Kelders still drives the company today: “What exists now, can be better tomorrow.”